In modern industrial environments, control panel boxes are the nerve centers that orchestrate machinery, power systems, and safety protocols. Every relay, switch, relay block, microcontroller, and wire matters—and even minor defects or misplacements can lead to costly downtime, safety hazards, or warranty disputes. Ensuring flawless Control Panel Box Inspection is crucial. That’s where Machine Vision Systems and Robotic Imaging Systems, powered by advanced AI, are setting a new standard in reliability, speed, and precision.

Let’s explore how Intelgic’s inspection platform transforms manual QA tasks into fully automated, traceable, and highly accurate visual inspection workflows.

Why AI-Powered Inspection Is Essential for Control Panels

Control panels are dense with components such as PCBs, relays, terminal blocks, circuit breakers, wiring harnesses, and DIN rails. Insufficient inspection of these assemblies may result in:

- System failure or dangerous electrical faults

- Fire risks due to short circuits

- Time-consuming rework or panel recalls

- Regulatory non-compliance or compromised warranty claims

Traditional visual inspection is labor-intensive and prone to omission—an unacceptable risk in critical applications like elevators, medical equipment, industrial automation, or aerospace.

The Power of Intelgic’s AI-Driven Inspection Solution

Intelgic presents a comprehensive, AI-powered Control Panel Box Inspection solution that ensures components are present, correctly placed, and free from defects. Here’s what the system offers:

Component Verification & Counting

- Detect missing, reversed, or misaligned components

- Count small parts (capacitors, ICs, terminals) and verify against the Bill of Materials (BOM) or reference template

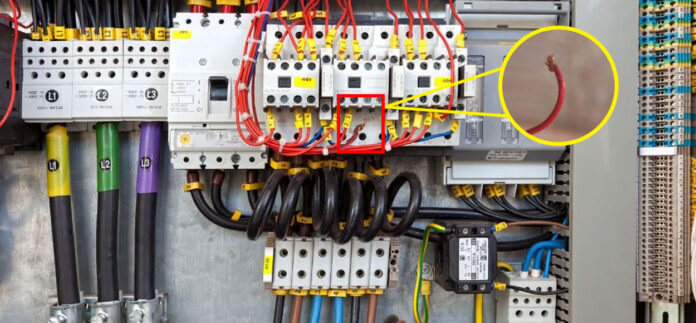

Wiring and Cable Inspection

- Verify routing, signal consistency, and connector positioning

- Detect loose or misconnected wires—critical for safe operation

OCR-Driven Component ID Validation

- Identify serial numbers, labels, and chip markers on PCBs and components to ensure correct parts are installed

PCB Surface Quality Checks

- Detect defects such as soldering issues, cracks, burn marks, discoloration, or delamination with precision image analysis

Enabling Technologies: Vision, Robotics, and AI

Multi-Camera Setups

- Combine area-scan and line-scan cameras to capture high-resolution images from different angles and distances—ideal for intricate or large panel assemblies

Robotic Imaging Systems

- Cameras and lighting modules move along X, Y, and Z axes via robotic rails or motorized stages. They operate under AI logic or PLC control, ensuring full coverage with optimal focus—even in deep cabinets

Specialized Lighting

- Uniform, reflection-free lighting (dome, backlight, coaxial) reveals fine details and minimizes visual interference

Core Intelligence: Live Vision AI Software

At the heart of the inspection is Intelgic’s Live Vision AI, a robust platform delivering real-time analysis and scalable control:

- Custom Model Training: Tailor models to diverse panel designs and layouts

- Template Matching & Zone-Level Analysis: Compare images with golden templates and isolate zones for detailed checks

- Defect Reporting: Generate annotated, location-specific insight with pass/fail results for each inspection

- Recipe Management: Store and quickly recall inspection setups for different panel variants

Multi-Sector Applications, One Proven System

Intelgic’s solution is adaptable across industries where panel reliability is mission-critical:

- Elevators & escalators

- Industrial machinery & automation

- Automotive control modules

- Power distribution panels

- Building Management Systems (BMS)

- Medical equipment control units

- Aerospace and defense panels

- Construction machinery controls

- Telecom infrastructure and energy systems

Tangible Benefits of the System

- Zero Defect Delivery: Catch errors before products leave the factory

- Reduced Inspection Time: Fast, automated scanning beats manual checks

- Scalability: Adaptable to any panel size or variant

- Seamless Integration: Connects with PLC, MES, and ERP systems for real-time operations

- Traceability & Audit Compliance: Captures inspection reports for serious quality control documentation

Enabling Smarter Vision with Intelgic Machine Vision Systems

This control panel platform builds upon Intelgic’s broader Machine Vision System expertise:

- Turnkey hardware/software package with AI capable of detecting defects from 10 microns to 10 millimeters

- Live Vision AI offers AI training, real-time classification, template recipes, zone-based analytics, and operator dashboards for inspection clarity

Best Practices for Deployment

- Map critical inspection zones on the control panel

- Select tailored imaging optics for accurate defect capture

- Calibrate lighting and camera paths for consistent coverage

- Train AI models with labeled data from real defects and reference panels

- Integrate with control systems for auto-routing of rejects or alerts

- Collect and analyze data to refine processes and improve manufacturing quality

Industry Trends & Insights

AI-driven inspection is reshaping manufacturing globally.

- Toyota, for example, uses robotic inspection systems with AI to verify parts from multiple angles with high adaptability

- Deep learning-based vision systems like YOLO enable real-time, high-accuracy defect detection—transforming inspection workflows across industries

Intelgic’s AI-powered Control Panel Box Inspection system—combining Machine Vision Systems and Robotic Imaging Systems—elevates panel inspection to a new level of precision and reliability. With uptime assured, defects minimized, and compliance streamlined, manufacturers can drive operational excellence and safety across sectors.